Top 6 advantages of a smart warehouse for your business

If you own a manufacturing, retail, transportation, or other business whose success depends on the timely delivery of goods, you may want to consider implementing digital technologies into your warehouses. Let’s take a closer look at the tech and smart warehousing benefits.

What is a smart warehouse?

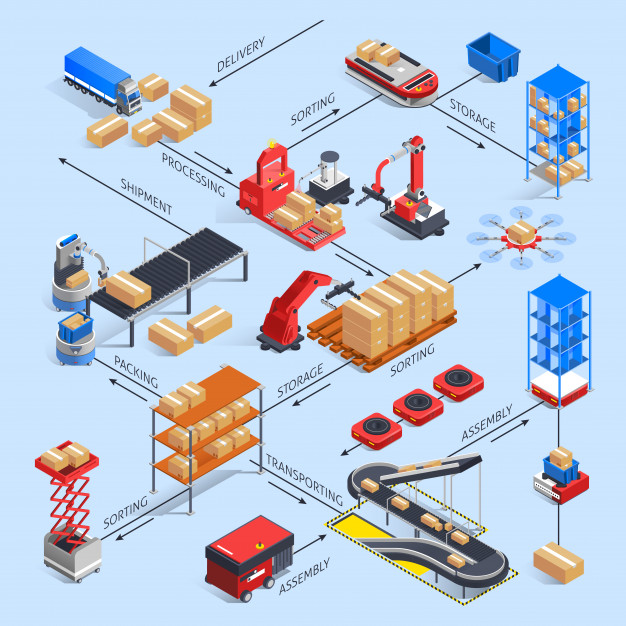

It’s an IoT-enabled warehouse that uses hardware and software technologies to automate workflows and drive efficiency. In a smart warehouse machines, computing devices, and objects are interconnected to make a single network. Via this network, you can transmit the instantly collected data, analyze it, and use it to your benefit. Many agencies still use traditional methods of managing warehouse space, sales, storing, picking, and supply chain planning. However, they can be enhanced with smart warehouse systems and increase their competitive advantage.

How does the system work?

A smart warehouse relies on technologies like sensors, RFID tags, and robots to monitor goods’ movement and inventory levels. This data is collected and transmitted to Warehouse Management Software (WMS), which generates instant reports on stock levels, order fulfillment rates, goods’ shelf life, and more. Using this information, warehouse managers can identify bottlenecks and optimize the flow of goods to ensure timely and hassle-free delivery of products.

6 major benefits of smart warehouses for businesses

Industries that use warehouses include manufacturing, retail, food and beverage, wholesale distribution, third-party logistics, healthcare, and hospital care. If your business belongs to one of the industries, check out the advantages of smart warehouse you can benefit from.

Warehouse optimization

Traditional warehouses are labor-intensive. They involve a lot of human workforce and manual operations that could lead to higher error rates. Smart warehousing reduces the need for human work. Entrusting repetitive tasks to smart Internet-connected machines prevents human errors caused by personnel.

The key point is not to replace your human employees but to add value to their work by doing more in less time. Instead of walking between the shelves in search of the item and then transporting it manually, they can simply find its location by the Internet-connected sensor and let a robot do the work. This way, you can speed up order processing and let your employees focus on more complex tasks that require human expertise.

Faster delivery, fewer returns — improved customer service

A survey conducted in 2021 found that over 40% of consumers in the United States anticipated their online deliveries to arrive within two to three days. Furthermore, around 27% of respondents hoped to receive their online purchases either on the same day or the following day. To meet high consumer expectations, businesses must provide faster shipping.

Order processing in traditional warehouses can be time-consuming, as workers spend a considerable amount of time walking around the entire warehouse to pick up products and fulfill orders. Picking errors can lead to further delays in processing, sorting, and packing orders which directly affects customer experience.

Smart warehouse solutions leverage advanced technologies to minimize picking errors and reduce the time required to pick orders manually. As a result, the orders are processed faster and more accurately, reducing the shipping time and return rate. This enhances the brand’s reputation and gives the business a competitive advantage over rivals.

Reduction of operating costs

A smart warehouse system contributes to cost savings. Thanks to smart equipment monitoring and advanced analytics, you can get timely alerts about a high downtime risk and save on equipment repair. Likewise, smart lighting and temperature sensors let you omit the waste of resources and ensure optimal conditions. For instance, once personnel leave your warehouse department, the IoT system could recognize this instantly through the movement sensors and turn off the lights.

Robotics and automated conveyor belts are frequently used in smart warehousing operations to move inventory from one location to another. This technology significantly reduces the need for human workers and enables warehouses to operate 24/7. As a result, the cost per unit of goods sold can be reduced by minimizing labor costs. This can lead to lower prices for customers and higher profit margins for the warehouse operator.

Real-time tracking throughout the supply chain

In traditional warehouses, employees have to wait for days or even weeks for reports to come. With IoT, you can get real-time data on the traffic flows and optimize them right away. For example, you might notice that large amounts of items are moved in the same trajectory simultaneously so you can distribute these flows between multiple branches for faster & safer goods arrival.

Tracking opens up immense opportunities in terms of sales and customer service. IoT sensors attached to products could send notifications to the central database once a particular item is back in stock. Through your WMS system, you can see the exact time and amount of delivered products and update your users on the new arrivals.

Better adaptability

Warehouses that are proactive in embracing new technologies and efficient space utilization are better equipped to respond to shifting market demands and operational adjustments. With customers becoming increasingly discerning, they are less likely to work with warehouses that are rigid and inflexible. A smart warehouse demonstrates your agility and willingness to adapt to the changing requirements of the business, which is crucial in today’s dynamic market.

Increased accuracy of warehouse operations

Ensuring high-quality data is crucial in leveraging the value of a warehouse. The quickly and accurately logged data gives more opportunities to use the information across various business departments. Optimizing cycle counts, for instance, minimizes the time spent by workers on manual inventory tracking. This frees up their time to communicate the updates with purchasing officers and other stakeholders who rely on these counts to make informed business decisions.

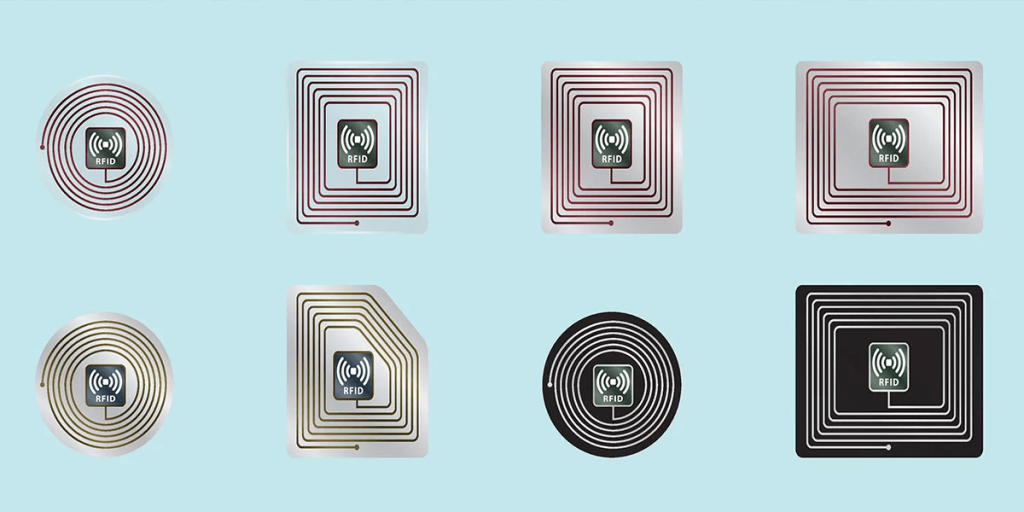

However, speeding up the manual processes often results in more human error. Smart warehouse addresses the issue in several ways, including barcode scanning solutions, RFID tags, sensors, and other smart devices and technologies that can track key performance indicators.

Key technologies of smart warehouse

RFID, IoT sensors, and AI algorithms are all smart warehouse technologies. Let’s explore them further.

AI-powered software

Artificial Intelligence analyzes the collected data to optimize your decisions. For instance, it can use previous-month ordering statistics, analyze reports, and make calculations and forecasts about the product demand for the next month. Thus, you can optimize your placement of goods and order amounts.

Another application is AI-powered robots. They can take into account the weight, size, type of each item, and even time of planned usage to find the optimal spot for storing and transporting it there quickly.

Guided automated vehicles (AGVs)

Automated guided vehicles, also called AGVs, such as pallet carts and forklifts are self-guided and follow digital paths within the warehouse. These vehicles load and unload containers, boxes, and pallets.

AGVs prove to be efficient in handling hazardous situations while minimizing material damage and improving inventory accuracy. Additionally, they help maximize warehouse space and reduce the need for new fulfillment and distribution facilities to be built.

IoT in warehousing

Warehouse processes can be optimized with IoT systems. If you need to speed up your packaging and shipping and deliver goods to customers fast and flawless, IoT might be just what you need.

Connected shelves can inform you of the low stock of items, theft, or damage every time it happens. IoT sensors have gained a longer battery life and their costs have decreased, so it’s a good place to start smart warehousing.

There are also connected AR glasses that show directions, scan barcodes, and provide instant data needed for inventory management. They enable hands-free experience for personnel and simplify their everyday duties.

IoT sensors installed inside the tracks help to monitor temperature and humidity conditions. This prevents any damage or food spoiled due to wrong transportation conditions. All the data is sent from IoT sensors to warehouse management software via the Internet.

Radio-frequency identification (RFID) tags

These are tags attached to individual goods or packages to transmit information to a central database. All the data is sent via electromagnetic signals. The products with RFIDs can also be scanned at a distance for easier storing, finding, and managing.

The technology allows scanning up to 200 tags simultaneously and tracking their location, number of days before expiration, and more. Based on this data, warehouse managers can make instant and accurate decisions.

There are passive and active RFID tags. While passive tags can only detect the presence of a tagged item within an area, active tags can also tell the exact location of the item. RFID tags continuously transmit the location info, so you get updated information on where exactly the package is.

Robots and drones

Modern robotics boost the speed and accuracy of warehouse operations and ensure the safety of workers and equipment. AGVs can collaborate with humans or other robots to move items around the warehouse. By using voice-automated order picking, a user can identify a pallet, which a robot can then lift and transport to the required location.

Drones can perform inventory-related tasks such as locating objects, conducting stocktakes, and performing cycle counts. Collaborative robots, or cobots, work alongside human workers to automate tasks such as machine feeding or material handling and complete laborious or repetitive tasks.

Within a warehouse, drones provide a safe and efficient way to access challenging and remote areas. Equipped with cameras, sensors, RFID, or barcode scanners, they are faster and more accurate than manual methods.

Warehouse management system

Basically, warehouse management software puts all your daily operations and processes into a single place for tracking and management. The system acts as a bridge between all the warehouse technology — hardware, software, sensors, ERPs, inventory management systems, and shipping software. WMS is aimed at bringing all the data into one platform for easy and handy access.

There are 3 types of WMS software you can use:

WMS system as a standalone solution

Such software works in isolation from other enterprise systems. It will require additional steps to customize and integrate with other processes.

Cloud-based WMS system

This system is more flexible, scalable, and relatively easy to recover in case of malfunctions.

WMS system integrated into ERP as a module

Via an ERP-based system, you can handle accounting, shipment, and parts that are still to be manufactured before the order is ready for delivery.

The choice of the system type depends on the tasks it should perform, so it’s better to consult a specialist to find out what would work best for you. The benefits of a smart warehouse management system include improved efficiency and productivity of warehouse operations, faster and more accurate data-driven decisions, higher accuracy, faster shipping, and more.

Summary of the benefits of smart warehousing

Smart warehouses offer clear advantages over traditional working methods. The key benefits of smart warehouse are

Process optimization

Higher competitiveness

Cost savings

Faster shipment and delivery

Data-driven approach to decision-making

Better adaptability to future challenges

By adopting smart warehouse solutions, warehouse operators can monitor KPIs and make data-driven decisions to enhance these metrics. Migrating to a smart warehouse can help achieve constant optimization and improvement of warehouse operations.